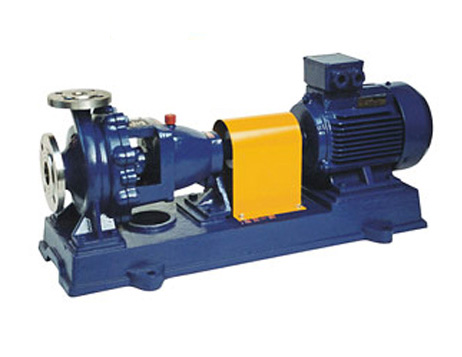

Vertical Marine Centrifugal Pump

I.Brief Introduction The vertical marine centrifugal pump is designed according to CB/T3523-2011. There are directly coupled and non-directly coupled structures to be selected for convenient installation. II.Use Range The vertical marine pump can be used as a bilge pump, ballast pump, cooling pump, fire pump, and general pump of the